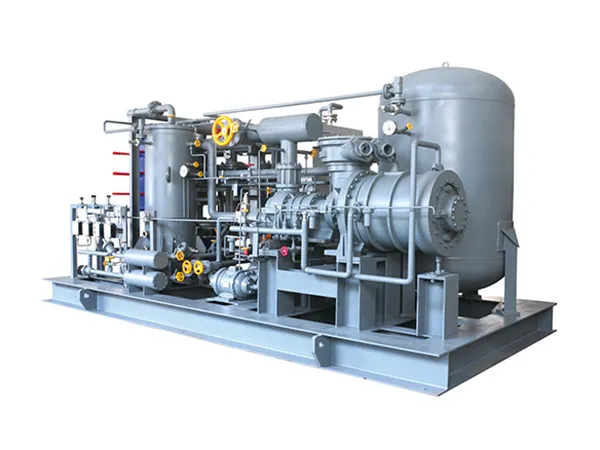

The non-energy gas compressor is designed for gas pressurization in various industrial applications, including production processes and exhaust gas recovery. It is widely used in industries such as petroleum, petrochemicals, natural gas, coal, chemicals, power generation, steel, and food processing.

This process gas compression equipment is capable of compressing a range of specialized gases, including carbon dioxide, vinyl chloride, ammonia, nitrogen, sulfur dioxide, hydrogen sulfide, hydrogen, helium and more.

The screw CO₂ compressor is widely used in industries such as petroleum, petrochemicals, natural gas, coal, chemicals, ammonia synthesis, power generation, steel, and food fermentation for the recovery and pressurization of carbon dioxide gas. It is a critical piece of equipment for producing industrial-grade or food-grade CO₂ and has been successfully implemented in multiple CCUS (Carbon Capture, Utilization, and Storage) projects.

To meet the stringent requirements of the food industry for lubricant quality, the compressor is equipped with food-grade lubricants and multi-stage oil separators, effectively reducing the oil content in the CO₂ gas output. This ensures compliance with food safety standards while maintaining efficient and reliable operation.

- Petroleum, petrochemicals, natural gas, and coal: Recovery of associated gas, flare gas, and CO₂ from acid gas removal processes.

- Chemical industry: CO₂ recovery from reaction tail gases in ammonia synthesis and fertilizer production plants.

- Power and steel industries: CO₂ recovery from flue gases.

- Food industry: CO₂ recovery from fermentation processes.

- Dry ice production: Recovery of CO₂ from flash steam.

| Suction Pressure | 0.04-2.0 MPa(a) |

| Discharge Pressure | Max. 5.2 MPa(a) |

| Compression Stage | Single stage, double stage |

| Volume Flow | 150-10000m³/h |

| Suction Temperature | -50~50℃ |

| Discharge Temperature | ≤ 40℃ (water cooled) |

| Ambient temperature: +15℃ (air cooled) | |

| Cooling method | Water cooling, air cooling |

| Volume flow adjustment (optional) | Slide valve: 15~100% |

| Slide valve + bypass: 0~100% | |

| Slide valve + variable frequency drive: 10~100% | |

| Explosion-proof grade | Exd IIBT4, Exd IICT4 |

Catalytic cracking flue gas recovery – 100,000 tons liquid CO₂ project

Catalytic cracking flue gas recovery – 100,000 tons liquid CO₂ project Ammonia synthesis CO₂ recovery project

Ammonia synthesis CO₂ recovery project Coal chemical tail gas CO₂ compression and liquefaction project – 100,000 tons food-grade CO₂

Coal chemical tail gas CO₂ compression and liquefaction project – 100,000 tons food-grade CO₂ CO₂ recovery for enhanced oil recovery project

CO₂ recovery for enhanced oil recovery project Ammonia synthesis low-temperature methanol wash CO₂ recovery and liquefaction project

Ammonia synthesis low-temperature methanol wash CO₂ recovery and liquefaction project Natural gas processing plant CO₂ recovery and utilization project

Natural gas processing plant CO₂ recovery and utilization project

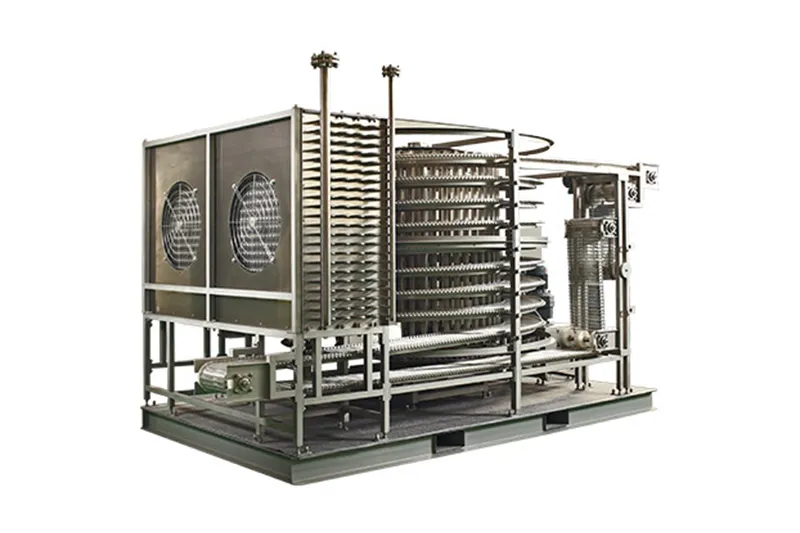

The helium compressor is used in helium recovery from natural gas, cryogenic superconductivity research, and the production of liquid hydrogen in cryogenic processes. It is designed to accommodate fluctuations in suction pressure, discharge pressure, and intake flow during operation.

Given helium's small molecular size and high leakage potential, the compressor is specially engineered with advanced design features and specialized manufacturing techniques. These ensure the unit operates efficiently, conserves energy, and minimizes the risk of leakage, making it a reliable choice for demanding industrial and research applications.

| Suction Pressure | 0.04-1.6 MPa(a) |

| Discharge Pressure | 0.1-2.5 MPa(a) |

| Compression Stage | Single stage, double stage |

| Volume Flow | 150-10000m³/h |

| Suction Temperature | 0 ~ 40℃ |

| Discharge Temperature | ≤ 40℃ (water cooled) |

| Ambient temperature: +15℃ (air cooled) | |

| Cooling method | Water cooling, air cooling |

| Volume flow adjustment (optional) | Slide valve: 15~100% |

| Slide valve + bypass: 0~100% | |

| Slide valve + variable frequency drive: 10~100% |