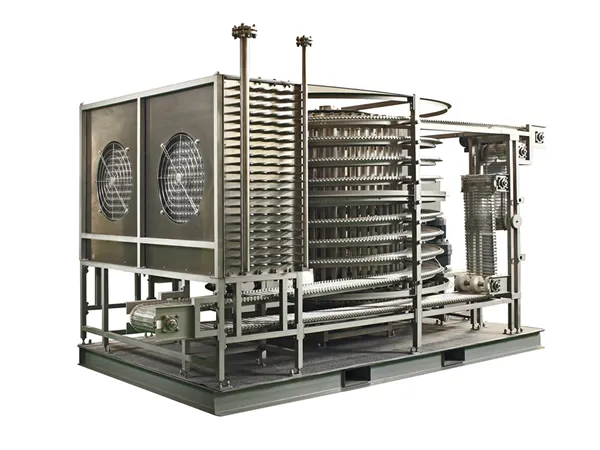

The production of beer and beverages relies heavily on ice water for cooling processes. Smaller facilities often use Freon or brine chiller systems, which are less energy-efficient. Larger operations typically adopt ammonia-based refrigeration systems capable of providing 2°C ice water to meet production requirements. To further enhance efficiency and minimize ammonia usage, a newly developed U-shaped plate heat exchanger system offers a compact design, precise temperature control, and high operational efficiency. This innovative solution supports energy conservation and improved performance in large-scale beverage production.

Ice slurry, composed purely of water without any additives, is a natural cooling system that maintains a consistent temperature of approximately 1°C as long as the ice remains intact. When stored in an ice tank, the slurry forms a loose mixture of ice and water, providing an ideal cooling solution for processes requiring temperatures between 2°C and 6°C, such as beer and beverage production. The DISU ice slurry system is a proven and widely adopted method, offering reliable and high-quality cooling for industrial applications.

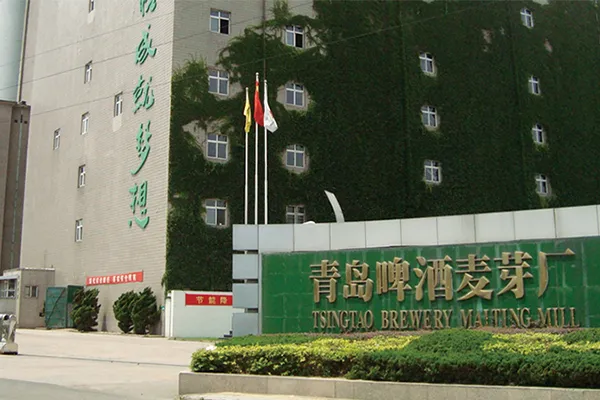

Tsingtao Brewery Co., Ltd.

Tsingtao Brewery’s main facilities nationwide utilize nearly 200 screw compressor units and refrigeration auxiliary equipment. These systems, developed and supplied by MOON-TECH, deliver comprehensive cooling and heating solutions tailored to meet the brewery’s production needs. Our commitment to reliable equipment and exceptional service has earned widespread recognition within the industry.