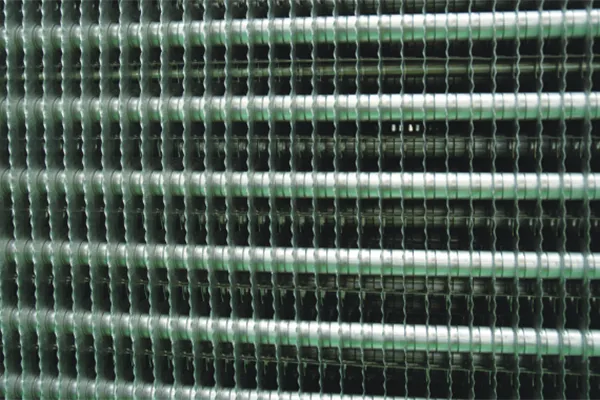

The mesh belt tunnel freezer offers an efficient and economical solution for rapidly freezing individual items or tray-packed products of various shapes and types. Designed for constant flow of goods, it seamlessly integrates into production lines, making it ideal for streamlined processing.

This tunnel freezer is primarily used for quick freezing prepared foods such as dumplings, buns, and rice balls. It is also highly effective for freezing individual or tray-packed meat and seafood products, ensuring quality and efficiency in large-scale production environments.

Mesh Belt Tunnel Freezer (Standard)

-

Belt Width 1.2-4m

-

Freezing Capacity 250-3000 kg/h (single belt), 500-6000 kg/h (double belt)

Mesh Belt Tunnel Freezer (High Efficiency)

-

Freezing Capacity 500-1500 kg/h

The high-efficiency mesh belt tunnel freezer is often paired with glazing machines and secondary freezing production lines, making it an essential component for advanced freezing processes. Compared to standard tunnel freezers, this high-efficiency model offers faster freezing speeds, reduced moisture loss, and better product quality. Its optimized design ensures consistent performance, making it ideal for industries requiring precise and efficient freezing solutions.

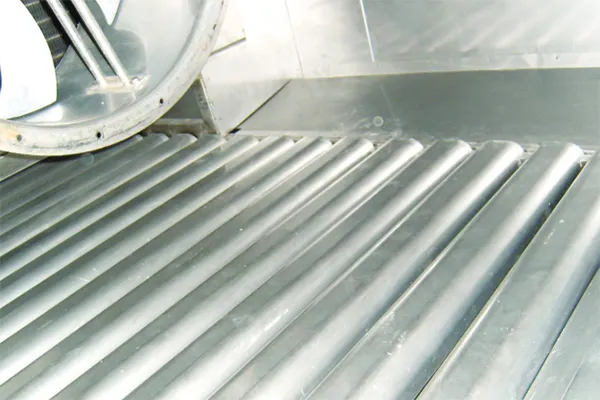

The plate belt tunnel freezer is specifically designed for the rapid freezing of seafood products such as scallops, shrimp, fish fillets, and fish portions. It is also ideal for freezing fried pastries and portioned meats, ensuring the integrity of delicate food products. The efficient design of this tunnel freezer makes it a reliable choice for industries requiring precision and consistency in their freezing processes.

Plate Belt Tunnel Freezer (Standard)

-

Freezing Capacity 250-800 kg/h (single plate belt), 500-1600 kg/h (double plate belt)

Plate Belt Tunnel Freezer (High Efficiency)

-

Freezing Capacity 400-750 kg/h (single plate belt), 800-1500 kg/h (double plate belt)

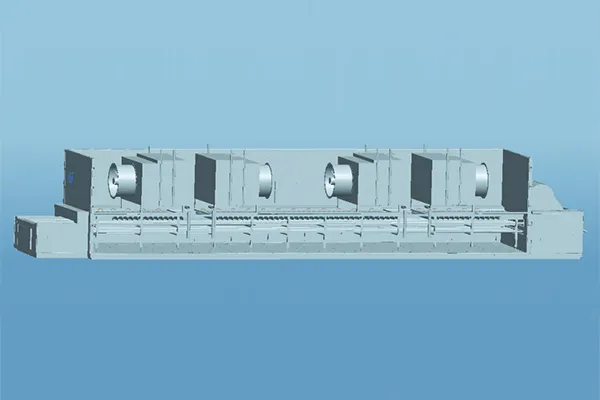

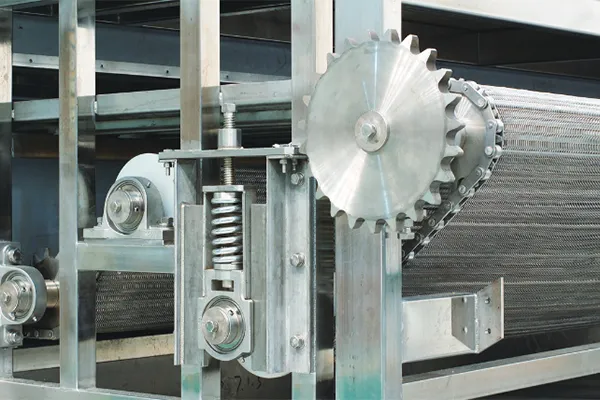

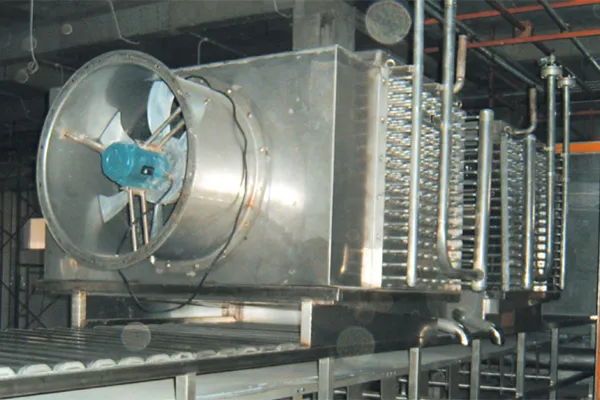

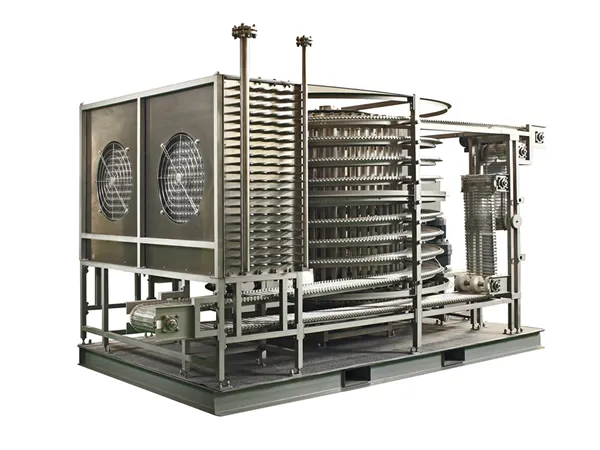

- The tunnel freezer consists of an inlet, insulation structure, outlet, conveyor belt, transmission system, air distribution system, evaporator, fan, and an electrical control system.

- Depending on the number of conveyor belts, it is available in configurations such as single plate belt, single mesh belt, double plate belt, and double mesh belt.

- The double plate belt and double mesh belt tunnel freezers divide the insulated structure into two relatively independent freezing chambers using insulated panels. Each chamber is equipped with its own transmission and air distribution systems. This design significantly reduces the required length of the processing area while meeting customer requirements for production processes and output capacity, making it an efficient solution for industrial freezing needs.