The DISU dynamic ice slurry units are designed to efficiently produce 0°C ice slurry, providing stable cooling for milk collection tanks, pasteurization processes, and storage areas. This system keeps milk temperatures below 4°C, meeting strict international quality standards. With a high storage capacity and the ability to operate at full load, the DISU system helps reduce production costs while ensuring consistent performance, making it an ideal solution for dairy processing facilities.

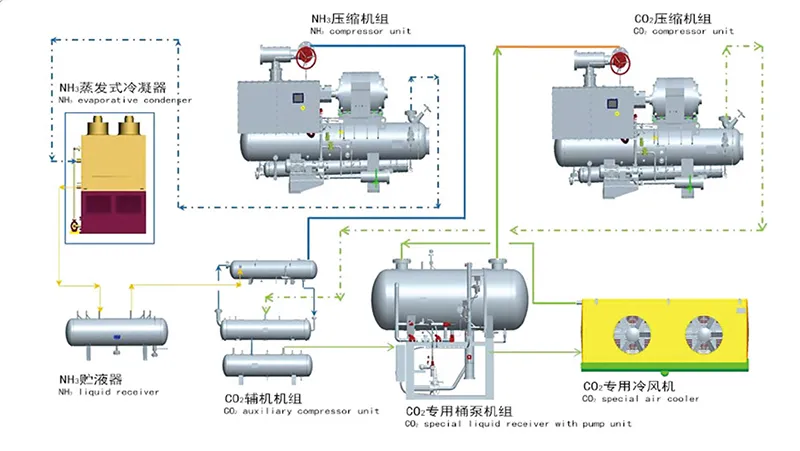

Refrigeration systems in dairy processing need to align with the specific requirements of each project. MOON-TECH focuses on designing systems with the right refrigerants and configurations to ensure efficiency and reliability. With growing emphasis on sustainability, safety, and energy efficiency, CO₂ refrigeration systems have become a standard for modern applications. These systems have advanced the adoption of updated refrigeration solutions for medium and large-scale commercial use, both domestically and internationally. The NH3/CO₂ cascade refrigeration system, for example, is ideal for hardening tunnels in ice cream production, providing precise temperature control and consistent performance for high-volume operations.

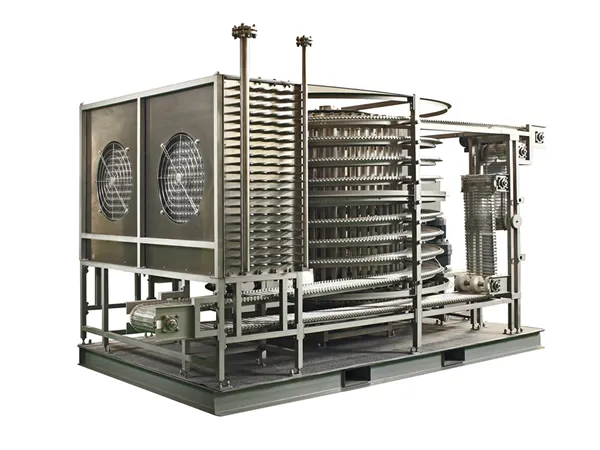

Individual Quick Freezers are among the most widely used equipment in prepared food processing. These systems efficiently freeze individual products while maintaining their quality and texture. To enhance performance, MOON-TECH has established a high-performance freezing laboratory capable of simulating various freezing conditions for different products. By analyzing freezing curves, IQF are designed with precision and adapted to meet specific processing needs.