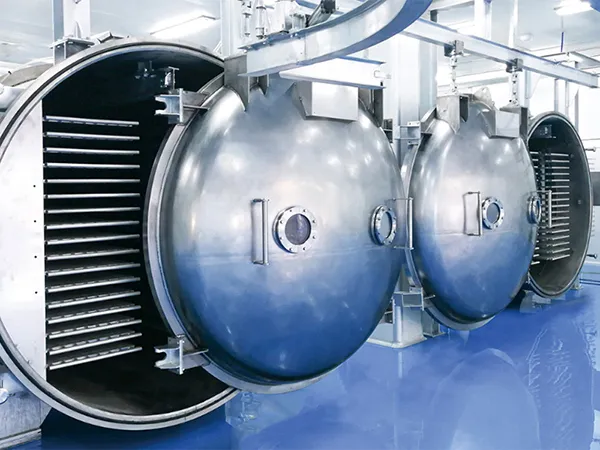

Controlled atmosphere (CA) storage is one of the most advanced methods for preserving fruits and vegetables. Beyond simple refrigeration, this technique regulates the storage environment by controlling temperature, humidity, carbon dioxide, oxygen, and ethylene levels. By slowing the respiration and metabolic processes of produce, CA storage helps maintain freshness and significantly extends the shelf life of fruits and vegetables.

Ice slurry systems are an effective solution for high-end pre-cooling in the fruit and vegetable industry. Immediately after harvest, ice slurry neutralizes the heat generated by respiration and transpiration, maintaining an optimal temperature of 0°C. This process not only preserves the natural shape and appearance of the produce but also doubles the shelf life of colors in fruits, vegetables, and flowers compared to untreated counterparts. Two primary methods are used for ice slurry pre-cooling: immersion cooling and low-temperature, high-humidity cooling. Each approach is tailored to the specific requirements of the produce being treated, ensuring maximum preservation and quality.

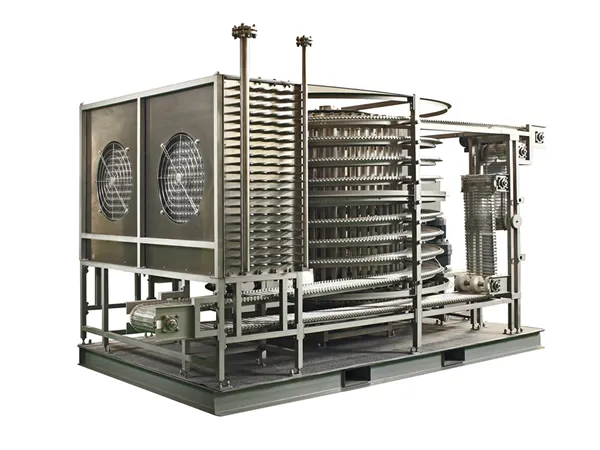

Fluidized bed freezers are designed for efficient and uniform freezing fruits and vegetables. The dual-stage system begins by quickly cooling the produce’s surface to its freezing point while using mechanical vibration to prevent items from sticking together. In the second stage, fruits and vegetables are deeply frozen to a temperature below -18°C, ensuring consistent results. This method works well for freezing items like green peas, chili peppers, spinach, carrots, broccoli, strawberries, mango cubes, and apple cubes. Using a CO₂ refrigeration system, these freezers deliver energy-efficient performance while maintaining the quality and texture of the frozen products.