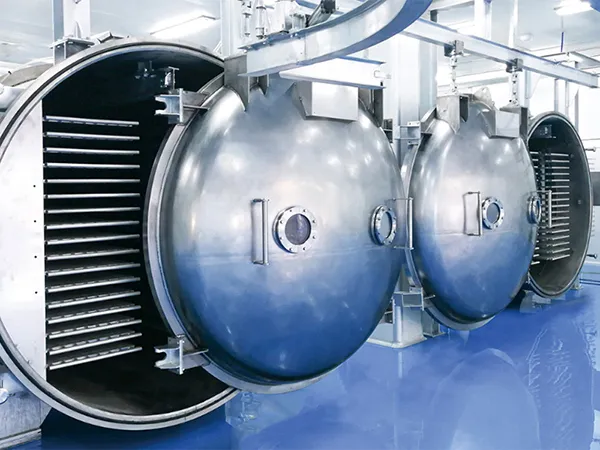

Adhering to HACCP standards is important for seafood processing plants, to ensure optimal levels of hygiene and safety for consumers. At MOON-TECH, we incorporate these standards into every aspect of our system design and equipment supply, including screw compressor units, process chiller units, process gas compressors, heat exchangers, and chiller and heat pump units. Drawing on decades of experience and a commitment to quality, we provide turnkey solutions that meet HACCP guidelines at every stage, from processing and freezing to storage and packaging, ensuring that our industrial refrigeration and heating systems consistently maintain optimal conditions.

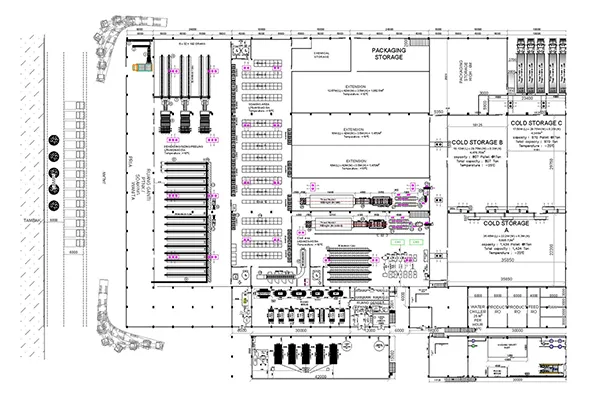

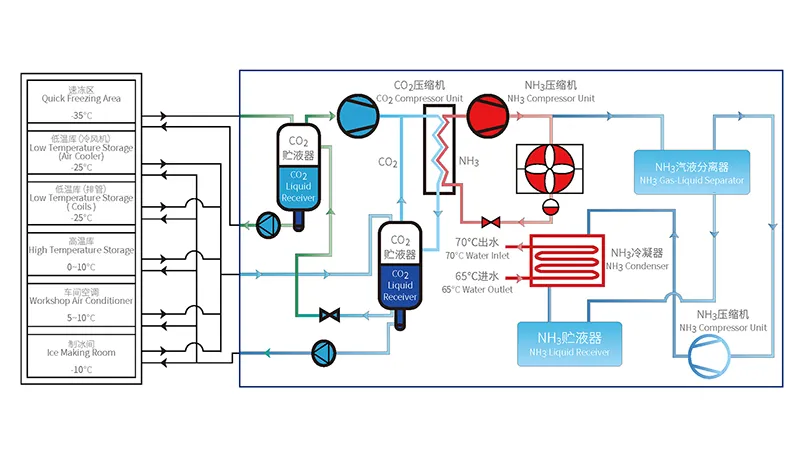

MOON-TECH designs refrigeration solutions tailored to the specific needs and characteristics of each seafood processing project. By selecting the most suitable refrigerants and systems, we ensure optimal performance and reliability. With the growing emphasis on environmental protection, safety, and energy efficiency, we have developed efficient CO₂ refrigeration systems. These systems are effective in low-temperature environments for medium and large-scale seafood processing applications, such as individual quick freezers, quick-freezing chambers, and cold storage facilities.

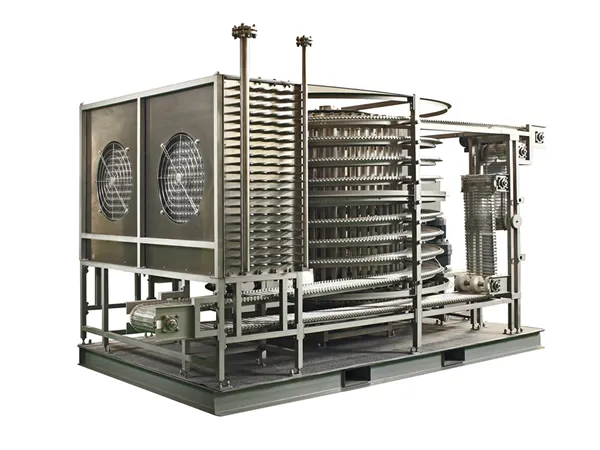

Quick-freezing is an important process in seafood processing, safeguarding the freshness, nutrients, and appearance of the products. MOON-TECH offers an extensive portfolio of specialized freezing equipment, including individual freezers, plate freezers, quick-freezing chambers, and smart freezing tunnels, each designed to meet diverse industry needs. The brine spray quick-freezing system combines a two-stage method: brine spraying followed by air cooling, providing exceptional speed and efficiency. This approach is particularly well-suited for large-scale shrimp production, ensuring consistent quality and operational efficiency for seafood processors.